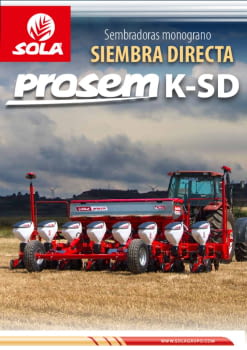

- Sembradoras

- Sembradoras monograno

- ACCESORIOS PROSEM

- Pre chassis SD

PRE-FRAME SD

The pre-frame SD is a compact direct seeding machine with a wide range of implements.

Its frame structure has a robust construction that makes it the best ally for direct seeding.

Row unit "K ELEKTRA"

- Articulated parallelograms system for great stability and amplitude of travel, ensuring perfect adaptation to the sowing surface.

- Row unit pressure load spring with adjustment via 6-position lever.

- Self-lubricating sintered bushing for durable articulation systems with zero maintenance during the sowing season.

- 50-litre seed hopper.

- Seed metering unit with suction dosing system, made of high resistance polymers for a long working life and minimum maintenance.

- Easy-access sowing disc inspection window.

- Extremely easy replacement of the sowing disc thanks to its patented fixing system.

- Emptying of the seed metering unit through a trap in the bottom of the metering unit.

- Continuous adjustment of sowing depth by means of a crank ensures seed planting is carried out correctly at the required depth (deep sowing kit option).

- Internal and external sowing disc cleaners made of anti-wear steel.

- Record of covering element pressure by spring and a 5-position lever.

- Regulation of the closing wheel angle by 4-position lever.

- External scrapers on depth control wheels.

- Semi-pneumatic depth control wheels Ø400x115 mm with bearings fitted with triple dust ingress protection.

- 15 Optimum furrow opening thanks to the low angle between the discs, which ensures a perfect seed emergence with the lowest power consumption, through Ø15" sowing discs with bearings fitted with triple dust protection.

- Interchangeable seed tube protective Suffolk coulter.

- Seed tube with anti-wear protection.

- Semi-pneumatic Ø13"x2" closing wheels with bearings fitted with triple dust protection.

- Planting depth controlled directly on the point of fall of the seed.

- Height-adjustable front clod remover with furrower blade to ensure correct preparation of the seedbed.

- Automatic element exclusion.

- Revolutionary step-by-step electric motor transmission system. The advantages of this system are numerous: long working life for motors, improved sowing precision, possibility of sowing by independent variable doses row by row, easy and simple adjustment of sowing rate from the tractor cab, ISOBUS communication protocol, section control row by row, pre-loading of the metering unit, statistical information on sowing activities.

- One standard sowing disc included.

Possibility of applying granular and micro-granular products.

Available in mechanical or electric drive with ISOBUS connection.

PRECHASIS SD Characteristics

PRECHASIS SD ELEKTRA Characteristics