TRI-2110

The TRI-2110 is a mechanical seed drill for conventional seeding.

With a seeding unit mounted in two or three rows, depending on the type of arm.

It can be equipped with a combined hopper.

Available with large capacity hopper (up to 1,860 litres).

Metering unit for various types of seed and fertiliser.

Optional symmetrical tramlines.

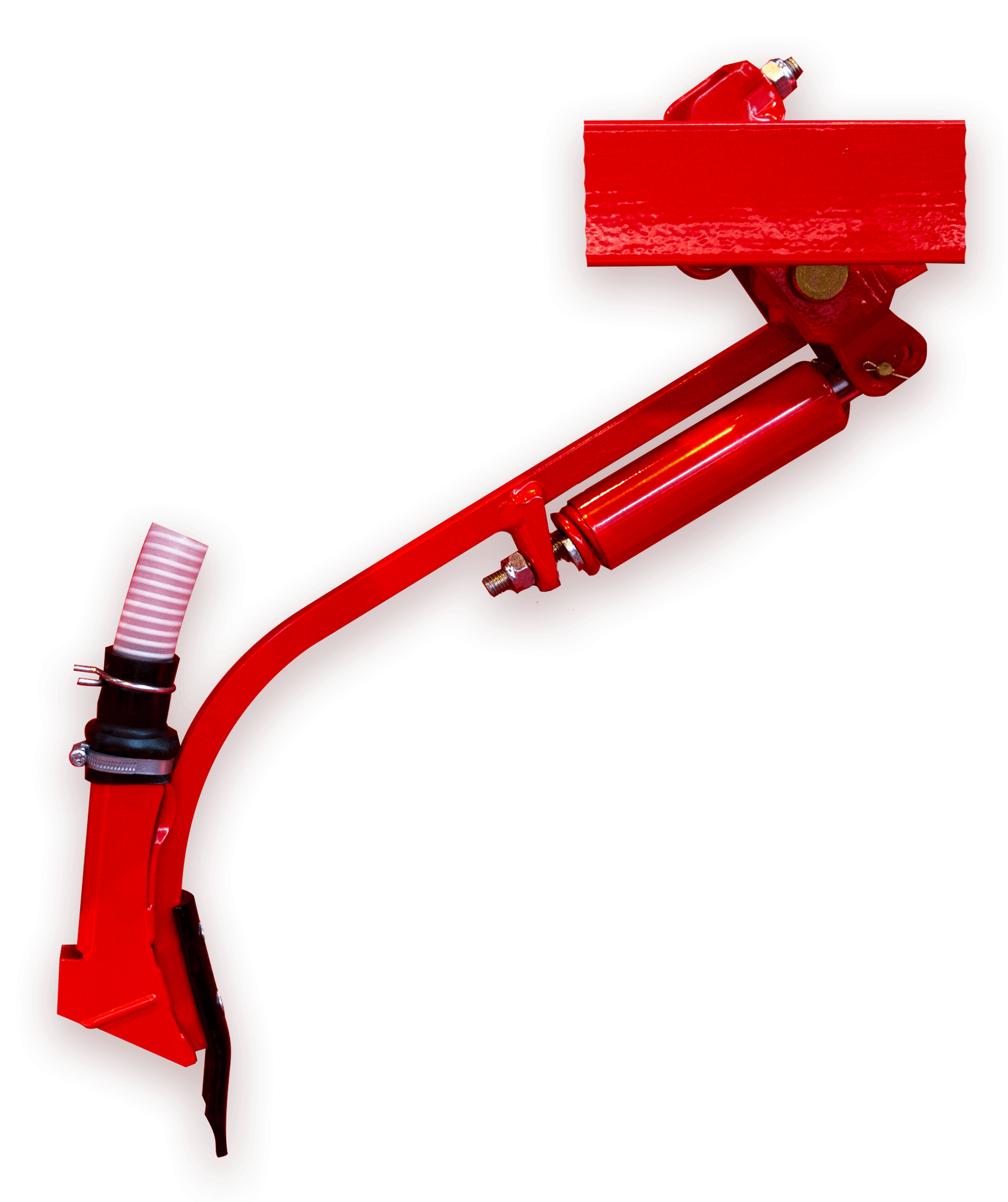

Straight Tine Coulter

Interchangeable tine coulter forged steel arm, with springs, for conventional sowing. It is the most widely used sowing gear as it allows sowing in very diverse conditions. Robust and suitable for prepared terrain. Its standard distance between sowing rows is 12.5 cm. Adjustable height on coulters behind the tracks. It is used on the pneumatic machines ARES 2713 and ARES-P, and mechanical machines such as the TRISEM-2110.

- High-strength sowing coulter.

- Tine coulter made of anti-wear material.

- Seed applicator Suffolk coulter.

- Flexible connection sleeve.

- Sleeve connection flange.

- Pressure spring with protective cover.

- Spring pressure adjustment.

- Attachment to Ares sowing bar using Ø14 mm U flanges.

- Seed transport tube made of anti-static material.

Double disc

Mounted on the TRISEM 2110 and ARGO. Rigid coulter with pressure spring, simple and light for conventional sowing and minimum tillage. It allows sowing with light plant debris due to the cutting capacity of the offset double disc. Adjustable rear wheel for better depth control.

- Double opening disc offset by 14” made of boron steel.

- Bearing with triple shielding to protect against dust.

- Pressure system with protected spring.

- Coulter made of high-strength forged steel.

- Sowing depth regulation without tools.

- Ø320 mm x 50 mm rear depth control wheel.

- Seed feed connection sleeve.

- Optional front opening tine coulter.

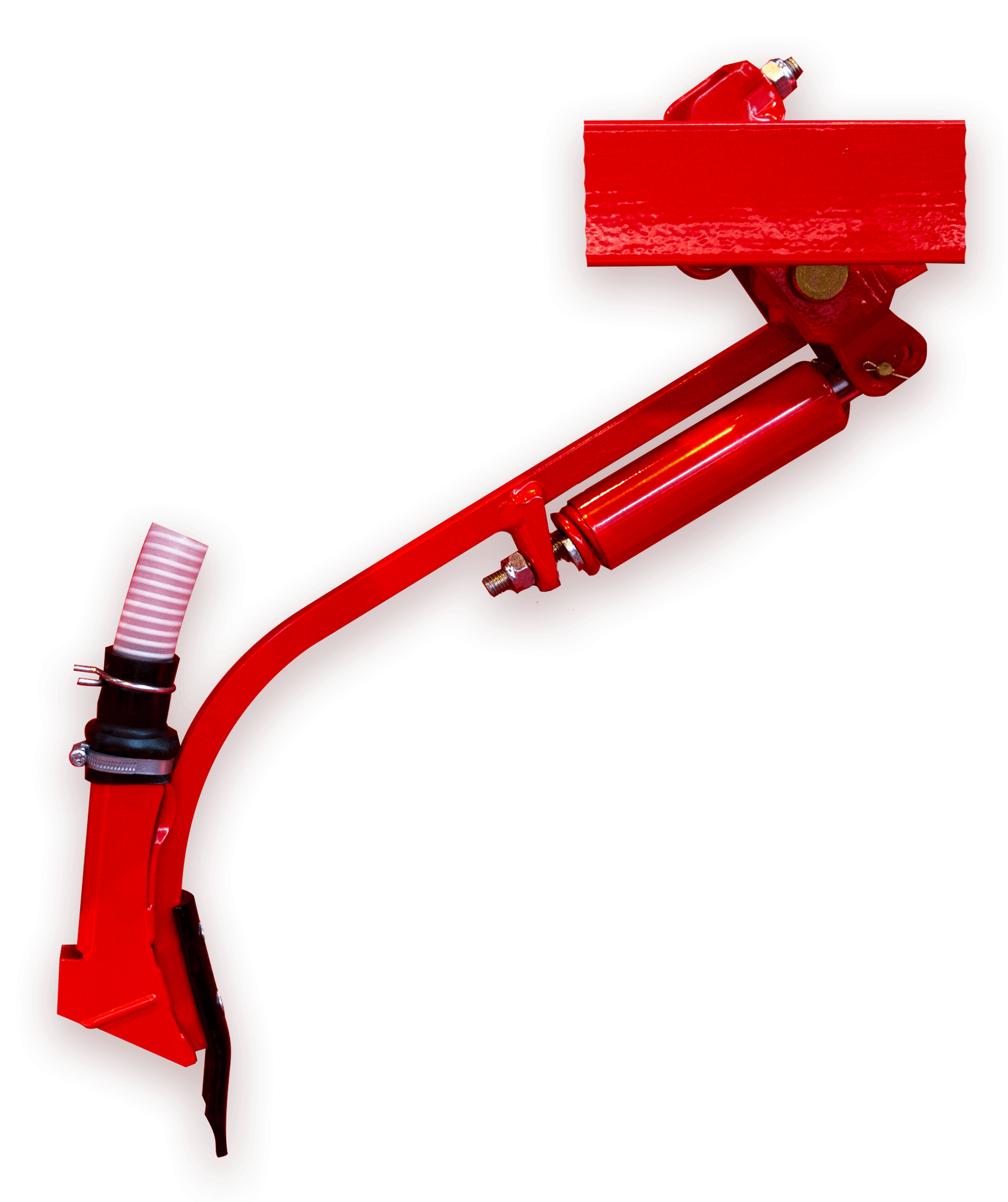

Saffolk Coulters

Mounted on the Suffolk coulter TRI-2110. Special coulter for conventional sowing. Very light and adaptable to the terrain. Excellent depth control on light or heavily worked terrain. It is recommended that they are installed with a front cultivator and leveller.

- Coulter made of a tubular steel structure.

- Furrower Suffolk coulter made of steel highly

- resistant to wear.

- Pressure regulation.

- Coulter drop adjustment.

- Seed tube connection bellows.

- Anti-recoil Suffolk coulter closure.