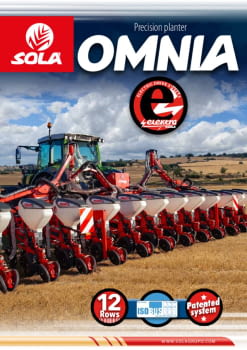

OMNIA

The PROSEM OMNIA is a foldable 12-row seed drill with a row width variable every 5 cm from 45 to 75 cm.

It is always equipped with the PROSEM K ELEKTRA seeding unit with electrical distribution and ISOBUS connection.

"K ELEKTRA" Row Unit

- Articulated parallelogram system that provides great stability and a wide range of travel for perfect adaptation to the sowing surface.

- Pressure loading spring of the seeding unit with 6-position lever adjustment.

- Self-lubricating sintered bushes that provide great durability to the articulation systems with zero maintenance during the sowing campaign.

- Seed hopper with a capacity of 50 litres.

- Metering unit with suction dosing system, built in high resistance polymers that give it a long useful life and minimum maintenance.

- Easily accessible seed disc inspection window.

- Extremely easy replacement of the seeding disc thanks to the patented seeding disc locking system.

- Emptying of the seed dosing unit by means of a flap in the lower part of the distributor.

- Continuous adjustment of the sowing depth by means of a crank handle that ensures correct seed implantation at the desired depth (high depth sowing kit option).

- Internal and external seeding disc cleaners made of anti-wear steel.

- Spring and 5-position lever to adjust the pressure of the plugging element.

- 4 position lever for adjusting the angle of the capping wheels.

- External scrapers on depth control wheels.

- Semi-pneumatic depth control wheels ø400 x 115 mm with bearings equipped with triple dust protection.

- Optimum furrow opening thanks to the low angle between the discs, which ensures perfect seed emergence with the lowest power consumption, by means of ø 15" sowing discs with bearings equipped with triple dust ingress protection.

- Interchangeable protective boot for the seed tube.

- Seed tube with wear protection.

- ø13" x 2" semi-pneumatic covering wheels with bearings equipped with triple protection against dust ingress.

- Planting depth controlled directly on the seed drop point.

- Height adjustable front tines with furrow-opening blade ensure correct preparation of the seed bed.

- Automatic element exclusion.

- Revolutionary transmission system with step-by-step electric motors. The advantages of this system are numerous: long motor life, improved seeding precision, possibility of seeding with independent variable rates row by row, easy and simple seeding rate adjustment from the tractor cab, ISOBUS communication protocol, row-by-row section cutting, pre-loading of the metering element, statistical information on seeding activities.

- One standard seeding disc included.

Large sowing width up to 9m.

Transport in 3m when folded.

Variable spacing with 12 rows.

Precision farming: variable metering and GPS-controlled cutting.

Characteristics