VESTA P

The VESTA-P is a seed drill with a 7,000 litres pressurised hopper made of high-strength steel.

This allows for increased precision in distribution and application rates.

The Vesta P is designed to excel in no-till, minimum tillage and conventional seeding.

7,000 litre pressurised hopper

Optionally divisible for seed and fertiliser at a ratio of 60% and 40%.

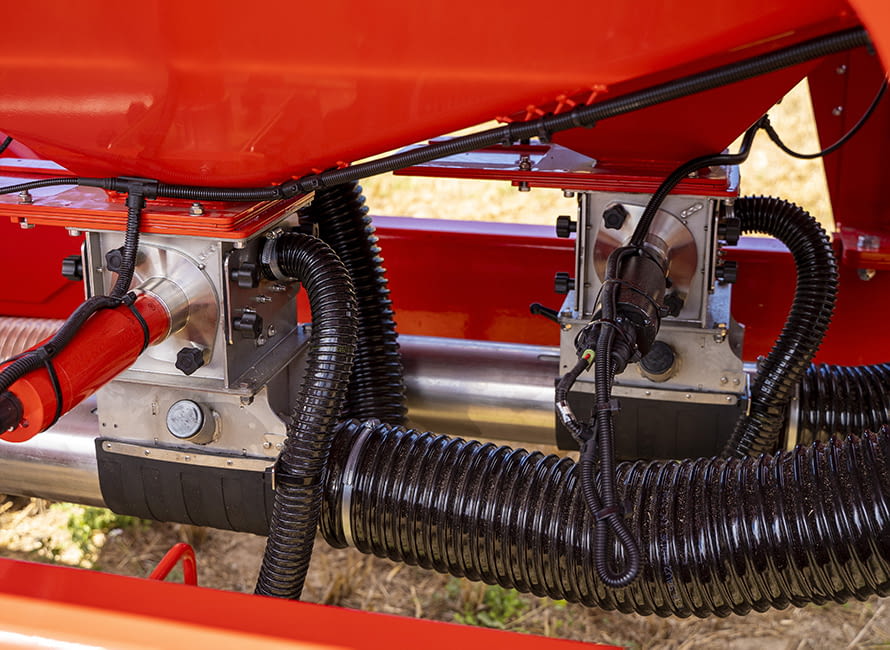

Reduced turbine oil flow requirement

Metering of up to 3 products simultaneously

ISOBUS electric metering unit

Floating frame in three sections

For non-Till sowing, minimum tillage and conventional sowing

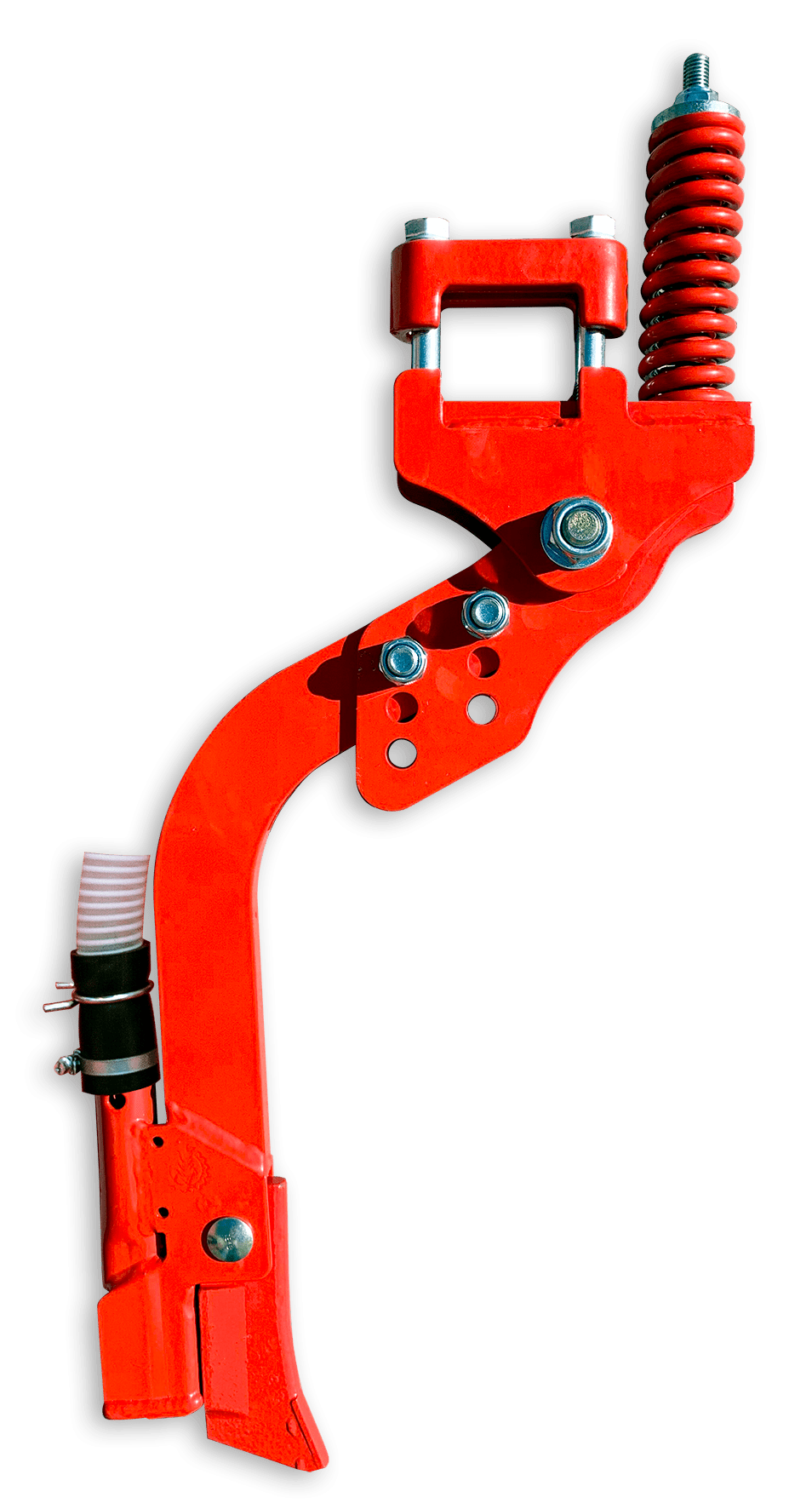

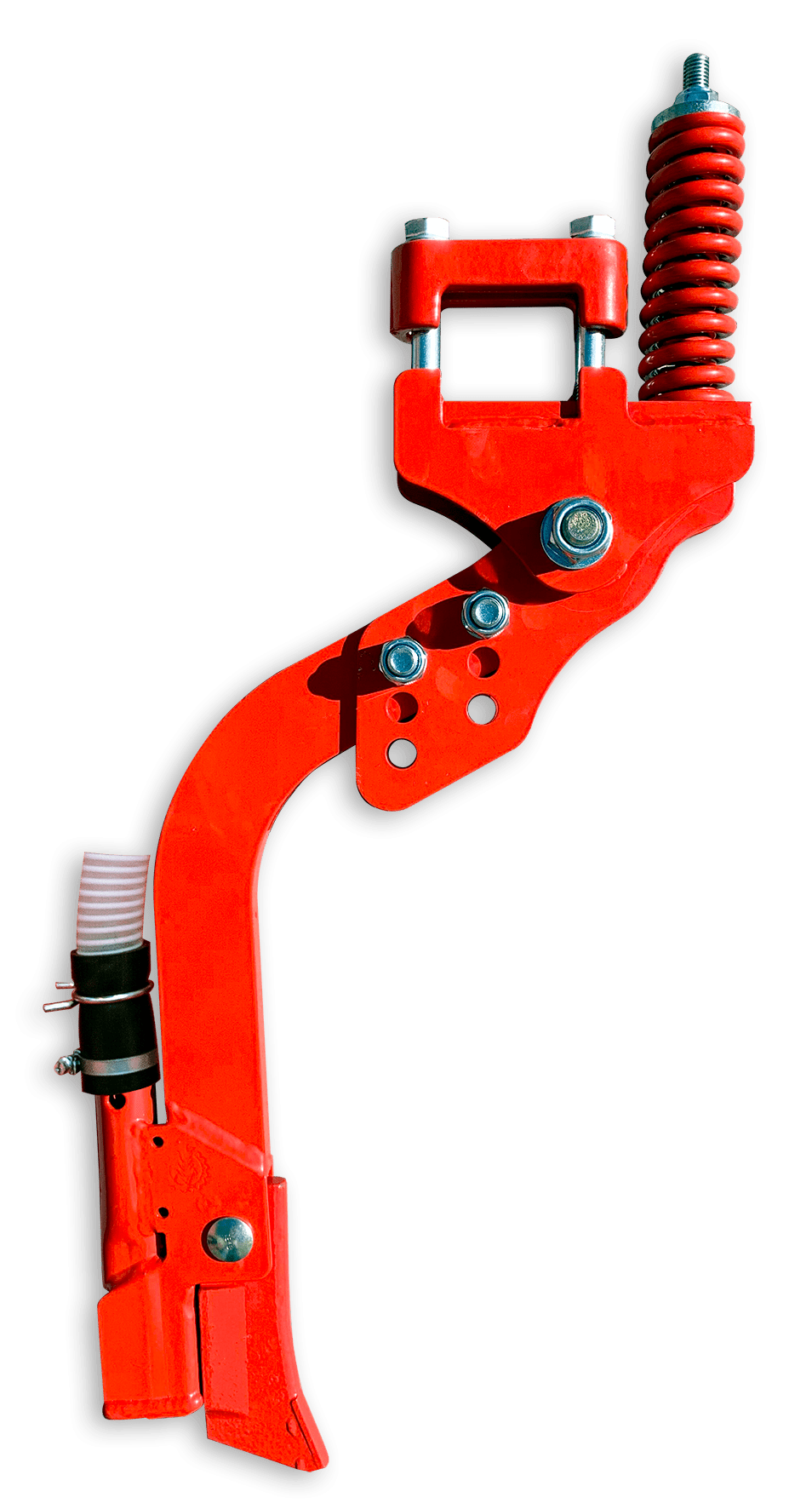

SM

Equipped on SM-1909, VESTA, VESTA-P, SM-P, CERES and SD-3115. More than 3000 machines on the market use this arm.

Multipurpose seeding arm, for direct seeding, minimum tillage and conventional seeding. Interchangeable Tungsten Carbide tip with high wear resistance and very easy to change by means of a single screw. The arms behind the roller have individual depth adjustment.

The 16 mm thick high resistance steel arm allows seeding in the most demanding conditions, with reduced maintenance costs.

-

Double seeding pressure spring.

-

Coulter made of high resistance steel.

-

Interchangeable anti-wear material coulter and tungsten carbide tip.

-

Applicator boot with anti-wear treatment.

-

High resistance connection sleeve and flange.

-

Seed transport tube in anti-static material.

-

Individual pressure adjustment of the sowing arm.

-

Individual depth adjustment (in adjustable versions).

Pressurized hopper

The hopper of the VESTA-P is a 7000 litre pressurized hopper which can be optionally divided into a 60%/40% proportion for seed and fertiliser. The pressurized system gives a better homogeneity in the distribution of the product and an optimal preservation due to its hermetic sealing. This technology reduces the tractor's hydraulic oil and fuel consumption.

Depth control on the lift

This system, which is fitted as standard on the VESTA, acts as a depth control on the linkage. It is adjusted by means of a plate and performs this function in addition to the main depth control system for the wheels of the sowing unit.

Sowing equipment characteristics

| 800/32 | 800/40 | 800/48 | 900/36 | 900/44 | 900/54 | |||||||

| Trailed hopper | ||||||||||||

| Seed hopper capacity (L) | 7000 | |||||||||||

| Seed/fertiliser hopper capacity (L) | 4380/2620 | |||||||||||

| Wheels | 560/60-R22.5 | |||||||||||

| Recharge height (cm) | 294 | |||||||||||

| Reload opening (cm) | 5 openings Ø56 | |||||||||||

| Metering unit type | With interchangeable modular rollers | |||||||||||

| Metering unit drive | Electric ISOBUS | |||||||||||

| Speed socket | 7 pins. | |||||||||||

| Turbine drive | Hydraulic | |||||||||||

| Required hydraulic flow (L) | 40 | |||||||||||

| Controller/Monitor | From ISOBUS monitor (not included as standard) | |||||||||||

| Total cutting of sowing | Standard | |||||||||||

| Half-width shut-off | Only available on machines with 2 distribution heads. Automatic when combined with GPS antenna. | |||||||||||

| Minimum power requirement (hp) | 200 | |||||||||||

| Removable selector sieve | Standard | |||||||||||

| Signal lights and work lamps | Standard | |||||||||||

| Dose calibration kit | Standard | |||||||||||

| Hole diameter for coupling pin (mm) | 32 | |||||||||||

| Seeding equipment | ||||||||||||

| Type of opening | SM | |||||||||||

| Working width (m) | 8 | 8 | 8 | 9 | 9 | 9 | ||||||

| Number of rows | 3 | 3 | 3 | 3 | 3 | 3 | ||||||

| Transport width (m) | 3,50 | 3,50 | ||||||||||

| Number of rows | 32 | 40 | 48 | 36 | 44 | 54 | ||||||

| Row spacing (cm) | 25,0 | 20,0 | 16,7 | 25,0 | 20,5 | 16,7 | ||||||

| Double spring harrow | Optional. First row of angled tines and second row of straight or angled tines. | |||||||||||

| Depth control wheels of the equipment: Quantity | 4 wheels on wings and 4 wheels in the middle | |||||||||||

| Track eradicator coulters | Optional | |||||||||||

| Approval for road transport | Check available approvals by market | |||||||||||