ELEKTRA SYSTEM FOR CEREAL

SOLA's ELEKTRA system has been developed

to meet the challenges of Precision Farming.

It consists of countless technological tools capable of controlling

seed drills in an easy, precise and intuitive way.

Electrical metering system

The highlight of this system is the stepper motor, which drives the seed metering unit. This solution gives the seed drill a number of advantages compared to other market offerings. Longer motor life, greater precision in rotation (no inertia or slippage) and greater precision in the rotation of the seed disc.

As the movement of the wheels does not need to drive the distribution system, there is a reduction in the number of moving parts of the seed drill. There are no chains, transmission wheels, clutches, etc. As a result, maintenance is reduced and wear parts are minimised.

In addition, it also offers the possibility of controlling the seed dose row by row by means of prescription maps or manually from the virtual terminal. In this way, each and every sowing row can adopt independent sowing rates.

AEF certified ISOBUS connection

This is the standard connection between our seed drills equipped with the Elektra system and your tractor. A very intuitive and user-friendly system with a graphical interface, which provides all the necessary information during sowing.

It offers the possibility of controlling all the inputs of the seeder (seeds, granulated fertilisers, micro-granulated fertilisers, liquid fertilisers, inoculants, insecticides, etc.) from a single monitor in the tractor cab. It offers very fast communication between the different components of the seeder and an alarm control system by means of numerical identification that facilitates diagnosis and troubleshooting.

These features are focused on facilitating and enhancing the work and control capacity.

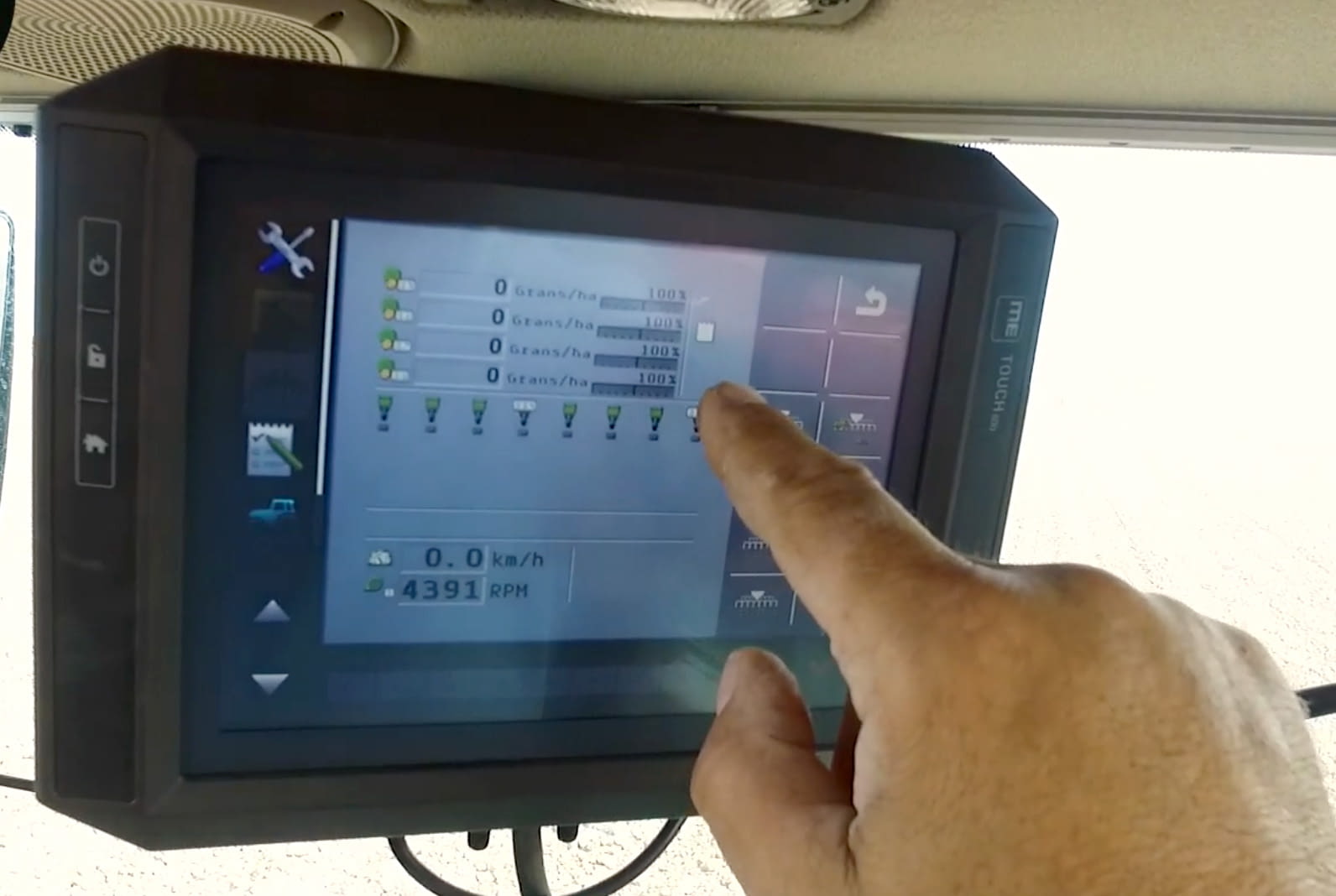

Control

From the same tractor cab and on a single terminal, all applications and work equipment are controlled. Possibility of modifying the dose of inputs by means of prescription maps, registering all the activities carried out by the machine, having fully configurable product databases... The control of your work will reach another level.

This system has the possibility of incorporating different speed sources (GPS antenna, radar, can bus, simulated) and different GPS receiver options adapted to customer needs according to the type of signal to be used (EGNOS, WAAS, GLONASS, TERRASTAR, RTK). If your tractor is not equipped with ISOBUS, you can optionally install various Universal Terminals available in 5'7", 8" and 12".

Efficiency

Control system based on the application of licences for use according to your needs: cutting of sections, single or multi-product variable dosage, task control, direction control, etc. Different guidance modes are available for manual or automatic options (contour, parallel, header, circle, etc.). More than 50 pre-set tramline rhythms and the possibility to customise other rhythms for special applications.