New high performance planters’ range

Designed to maximize the yield potential by planting with perfect seed singulation and spacing while maintaining a constant depth and seed-to-soil contact.

.

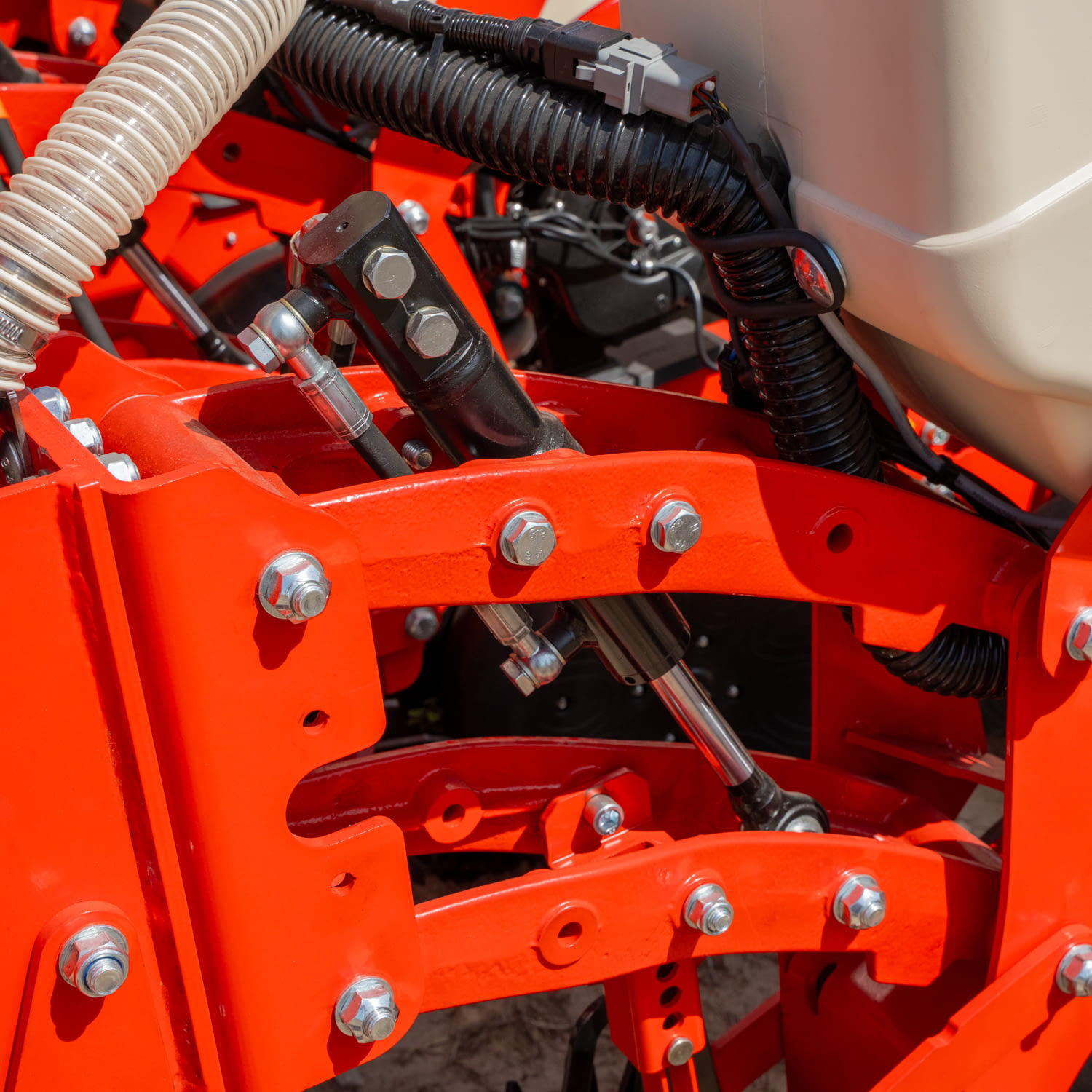

Advanced row unit design

| 1- Hydraulic downforce. Maintaining consistent depth with up to 350kg downforce. |

| 2- Heavy duty parallel linkage. Reinforced cast iron arms for increased durability and reliability. |

| 3- Floating row cleaners. Exceptional residue cleaning stars in toughest conditions. Optional side wheels for improved quality and stability. |

| 4- Unique design 15’’ double disc openers with 9º between discs. Better seed placement with less compaction and soil disturbance. |

| 5- Ground wheels and opener discs bearings with reinforced triple seals. Extra protection for longer life and lower maintenance costs. |

| 6- Intermediate press wheels. Seeds are pressed into the bottom of the furrow ensuring constant depth and seed to soil contact for faster and uniform emergence . |

| 7- Microgranular products hoppers. Up to two 20L hoppers, each featuring Isobus compatible electric drives with easy to adjust universal auger meter and up to 3 application points. |

| 8- Large capacity hoppers 70L. More productivity and less refills, protected by moisture-tight covers with locks. |

| 9- Most accurate and easy to use vacuum meters feature self-adjusting seed singulator and ejector wheel. Simple and reliable design allow for high precision seed metering at high working speeds and seeding rates. |

| 10- Exclusive stepper motors with high torque at wide range of working speeds ensure high quality seed distribution across the field. |

Tailored choices with one row unit

Wide range of options allows to specify planter for any customer needs, whether it is conventional, reduced tillage and direct seeding practices.

Planting perfection

The quality of the seed dosage has a direct impact on the final result. Each double seed reduces the yield potential of affected plants by 40-80%, and each omission results in a loss of yield opportunities of up to 100%. Each percentage improvement in seed singulation can increase yield potential by 1% or more. You can achieve up to 99% accuracy with our new Precision Planting distributor.

Hydraulic downforce

To maintain uniform depth VELOX is equipped with Hydraulic downforce system, with hydraulic cylinders ensuring equal pressure applied to every row, regardless of changing field conditions. Combined with tractor-to-planter Adaptive Weight Transfer system it can deliver up to ample 350kg pressure per row – sufficient to work in most challenging environments.

Seed meter

New vacuum seed meter by Precision Planting achieves accuracy of ≥99%. Benefit from the proven performance and reliability in metering various types and sizes of seeds. Velox seed meter is simple to adjust and maintain, as the seed singulator does not require adjustments. Additionally, it features a seed ejector wheel to clean seed disk holes and avoid skips.

Microproducts hoppers and meters

Ensuring that plants have proper protection and access to the specific nutrients at each growth stage is vital for their development and maximizing yield potential. Up to two micro-products can be applied either in the furrow between the closing wheels or seed openers, or over the furrow behind the closing wheels. Application of insecticides to protect seeds, starter fertilizers to support early plant development promote rapid plant’s growth. Each product is precisely metered by Isobus-compatible electric motors with section or row-by-row control, optimizing input utilization, reducing waste, and protecting the environment.

|

MODELS |

300/6 45-75 |

300/6 50-80 |

300/7 45-60 6F70-80 |

300/7 S 50-80 |

300/8 40-75 |

300/9 40-55 |

300/8 70-80 |

300/9 60-65 |

300/12 45-50 |

|

Frame type |

Telescopic | Telescopic, double |

Foldable |

||||||

|

Number of rows |

6 |

6 |

7 |

8 |

8 |

9 |

8 |

9 |

12 |

|

Row unit type |

VELOX |

||||||||

|

Row spacing adjustment |

Hydraulic, with 5cm increments |

Manual, continuous |

|||||||

|

Row spacing |

45-75cm |

50-80cm |

7 rows 45-60cm |

50-80cm |

40-75cm |

9 rows 40-55cm |

70-80cm |

60-65cm |

12 rows 45-50cm |

|

Seed meter |

Vacuum meter with electric motor drives |

||||||||

|

Seed hoppers |

70L each, with moisture-tight lids and locks |

||||||||

|

Row unit downforce |

Hydraulic cylinders on each row, up to 350kg pressure / Springs with 6 settings, up to 250kg pressure |

||||||||

|

Weight transfer system |

Hydraulic with proportional weight transfer, up to 1000kg additional frame load |

||||||||

|

Closing system |

Two closing wheels with angle adjustment and 6 downforce settings up to 53kg |

||||||||

|

Fertilizer system |

High-capacity system with the choice of frontal or planter mounted hoppers |

||||||||

|

Planter mounted hopper |

1400L, air pressurised hopper |

N/A |

|||||||

|

Frontal hopper |

AURA, 2000L air pressurised hopper |

||||||||

|

Fertilizer metering |

Modular volumetric meters, ISOBUS electric drives |

||||||||

|

Fertilizer distribution |

Air flow, hydraulic driven turbine |

||||||||

|

Fertilizer openers |

16’’ single disc openers or 15’’ double disc openers |

||||||||

|

Micro products application |

Up to 2 hoppers per row, 20L each, ISOBUS electric drives, with 3 different application points |

||||||||

|

Row Cleaners |

Floating design with easy height adjustment, 350mm stars with optional 255x45mm side wheels |

||||||||

|

Turbodisc + Row Cleaners |

Includes 16’’ single disc coulter with 4 depths adjustments & row cleaners |

||||||||

|

Hydraulic row markers |

Option |

||||||||

|

Tractor power requirements |

≥ 120 hp |

≥ 130 hp |

≥ 140 hp |

≥ 160 hp |

≥ 180 hp |

||||

|

Tractor hydraulic system requirements |

Requires “Closed Centre” hydraulic system, max 40 l/min flow (70l/min with fertilizer system) |

||||||||

|

Number of hydraulic outlets |

1 double acting - frame folding (standard) |

||||||||

|

1 double acting – vacuum turbine (standard) |

|||||||||

|

1 double acting – fertiliser turbine (optional) |

|||||||||

|

1 double acting – row markers (optional) |

|||||||||

|

1 – free return line (standard) |

|||||||||

|

Transport width |

3.0m |

||||||||

| Características | PF 300/8 | PF 300/9 | PV 300/12 |

|---|---|---|---|

| Tipo de chasis | Posición fija de los elementos, chasis plegable para transporte | Posición variable de los elementos mediante un husillo, chasis plegable para transporte | |

| Categoría de enganche | Cat III. | ||

| Elemento de siembra | VELOX | ||

| Ancho del transporte (m) | 3 | 3 | 3 |

| Número de líneas | 8 | 9 | 12 |

| Distancia entre líneas según equipamiento seleccionado (cm) | 70-80 | 60-65 | 12 a 45-50 / 9 a 64-65 / 8 a 70-80 |

| Cambio distancias entre semillas | Desde monitor ISOBUS (no incluido de serie, ver cap.“Monitores de control”) | ||

| Accionamiento de la turbina | Hidráulico | ||

| Cantidad de ruedas de apoyo o transmisión | 2 de apoyo | ||

| Medidas de las ruedas | 23 x 10.5 | ||

| Peso de la máquina base sin opcionales (kg) | 1960 | 2080 | 2490 |

| Accionamiento del dosificador de semilla | Eléctrico ISOBUS | ||

| Toma de velocidad | 7 pines. Otras opciones disponibles en cap. "Receptores GNSS" | ||

| Control de siembra | Desde monitor ISOBUS (no incluido de serie, ver cap.“Monitores de control”) | ||

| Compatibilidad ISOBUS | Verificar compatibilidad entre ECU y terminal ISOBUS del tractor - Ver cap. "Cuestionarios compatibilidad ISOBUS" | ||

| Requisitos hidráulicos del tractor | Turbina Hidráulica: 1SE + Retorno Libre / Apertura chasis: 1DE / Presión elementos: 1DE / Trazador: 1DE | ||

| Control de aspiración de la turbina | Vacuómetro analógico de serie | ||

| Corte de secciones | Desde monitor ISOBUS (no incluido de serie, ver cap.“Monitores de control”) - Necesita licencia, toma de velocidad y posicionamiento | ||

| Dosis variable | Desde monitor ISOBUS (no incluido de serie, ver cap.“Monitores de control”) - Necesita licencia, toma de velocidad, posicionamiento y mapas de prescripción | ||

| Generador de energía | Des de la toma Isobús / Línea adicional des de la bateria del tracor (según opcionales) | ||

| Capacidad de la tolva para semilla (L) | 70 | ||

| Ruedas de control de profundidad | En opción: 400 x 115 ciegas/con radios o 400 x 65 | ||

| Ruedas tapadoras traseras | Ver cap."Opcionales" | ||

| Presión del elemento | Cilindros hidráulicos en cada fila, hasta 350 kg de presión / Muelles con 6 ajustes, hasta 250 kg de presión | ||

| Trazadores hidráulicos | Opcional, con disco liso a rueda de tractor (1) | ||

| Luces de señalización | De serie | ||

| Discos de siembra | 1 juego de discos de maíz incluido por máquina (Ver cap."Discos de Siembra") | ||

| Capacidad de la tolva para micro (L) | 20 | ||

| Accionamiento del dosificador de la abonadora | Eléctrico ISOBUS | ||

DEUTSCHER VELOX KATALOG low.pdf

15.06 Mbytes

DEUTSCHER VELOX KATALOG low.pdf

15.06 Mbytes

VELOX BROCHURE low.pdf

15.05 Mbytes

VELOX BROCHURE low.pdf

15.05 Mbytes

VELOX CATALOGO low.pdf

15.03 Mbytes

VELOX CATALOGO low.pdf

15.03 Mbytes

VELOX CATALOGUE low.pdf

15.05 Mbytes

VELOX CATALOGUE low.pdf

15.05 Mbytes

POLSKI VELOX KATALOG low.pdf

2.03 Mbytes

POLSKI VELOX KATALOG low.pdf

2.03 Mbytes

VELOX BROCHURE IT v03.pdf

2 Mbytes

VELOX BROCHURE IT v03.pdf

2 Mbytes

VELOX BROCHURE RO v03.pdf

2.03 Mbytes

VELOX BROCHURE RO v03.pdf

2.03 Mbytes

VELOX BROCHURE RU v03.pdf

2.03 Mbytes

VELOX BROCHURE RU v03.pdf

2.03 Mbytes

VELOX BROCHURE UKR v03.pdf

2.04 Mbytes

VELOX BROCHURE UKR v03.pdf

2.04 Mbytes

VELOX BROCHURE v03 BULG.pdf

2.03 Mbytes

VELOX BROCHURE v03 BULG.pdf

2.03 Mbytes

VELOX BROCHURE CAT v03.pdf

2 Mbytes

VELOX BROCHURE CAT v03.pdf

2 Mbytes